Wax

Here’s TreeHouse’s specialty. Instead of a membership to the gym to grow our shoulders, we get our workouts from hand-rubbing oil and wax finishes over dyed wood. Most companies that offer such finishes charge more than wraps, but we’re the opposite on this point. Wrap material can be pricey, so they are in our medium- and higher-priced categories. It’s a lot more labor to prepare, dye, oil and wax wood, but the material is less expensive; we charge you less.

To begin, there are several steps in all of this, where the final one is the actual finish. Although, "Finish" is a word that gets tossed around to talk about pinstriping, paint job, images, clearcoat etc., what we mean with the term is the actual final stuff that can be relatively measured in amount of light dispersion. The differences on this page are from which wax recipe is used. In other words, a blue can have a Matte Wax finish or a Satin Wax finish--but the same blue.

Our process breaks down into three stages:

To begin, there are several steps in all of this, where the final one is the actual finish. Although, "Finish" is a word that gets tossed around to talk about pinstriping, paint job, images, clearcoat etc., what we mean with the term is the actual final stuff that can be relatively measured in amount of light dispersion. The differences on this page are from which wax recipe is used. In other words, a blue can have a Matte Wax finish or a Satin Wax finish--but the same blue.

Our process breaks down into three stages:

1. Dye

|

It’s kinda funny—we call the first room in the basement workshop the “Paint Room,” but we very rarely use paint. “The Dye Room” just sounds too...Halloween-y, but it’s actually more accurate. Most TreeHouse Drums are either left natural or dyed with color before being sealed with one of a few multi-step oil-n-wax finishes. Let’s start with the color. Our typical colorant is the same Aniline Dyes that Fender and Gibson use in their custom shops. This stuff is a class of material that works similarly to a stain, but better for our purposes. A store-bought wood stain has pigment, and usually a binder to glue that pigment to wood, that’s suspended in a solvent. The stains’ pigments sit on the surface of wood and usually obscure the wood’s grain. Dye is quite different. Dye is made up of microscopic crystals that dissolve in a solvent. As a result, dye travels wherever the solvent travels, and that’s deeper into the wood than stains. Now you can see both the color and woodgrain aplenty. We’re talking about changing the color of the cells of the wood, not just leaving something behind for you to look through to see wood. No color will stay sharp eternally in the presence of UV radiation; it’s not that Aniline Dyes don’t fade, they just cause their projects to hold their color much longer than stains.

|

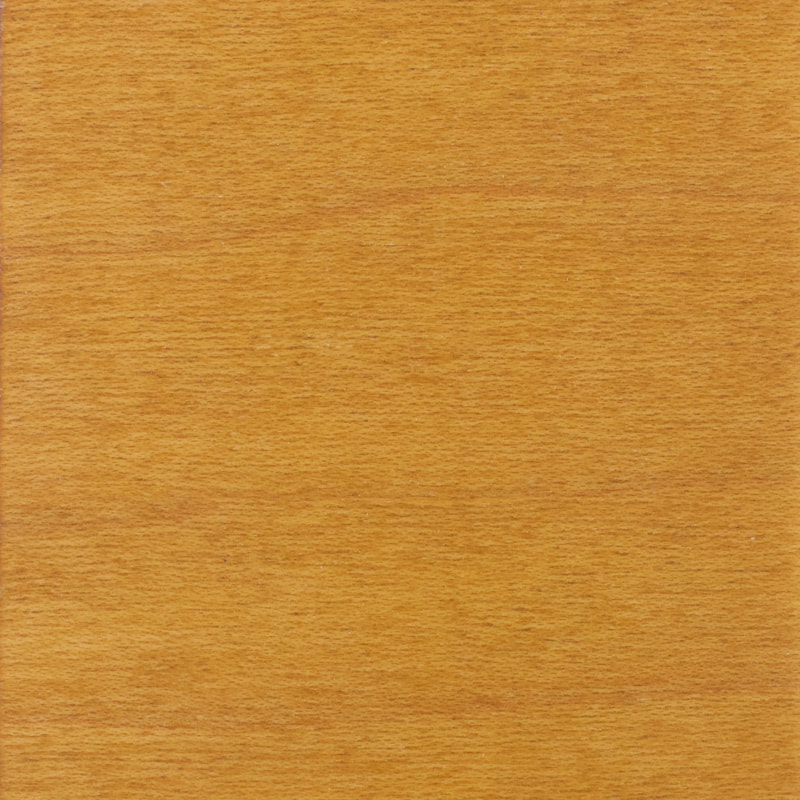

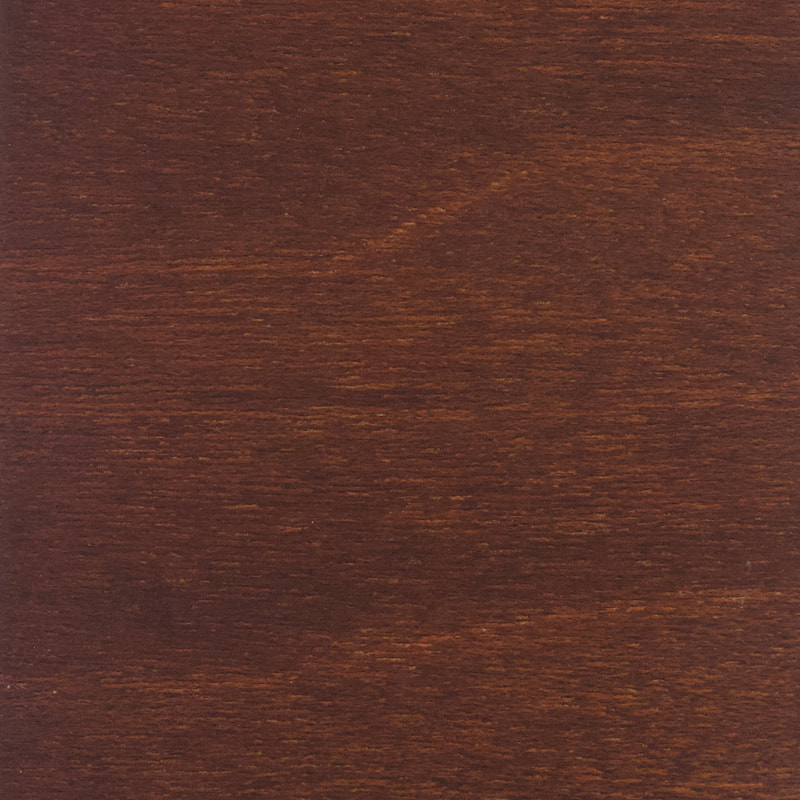

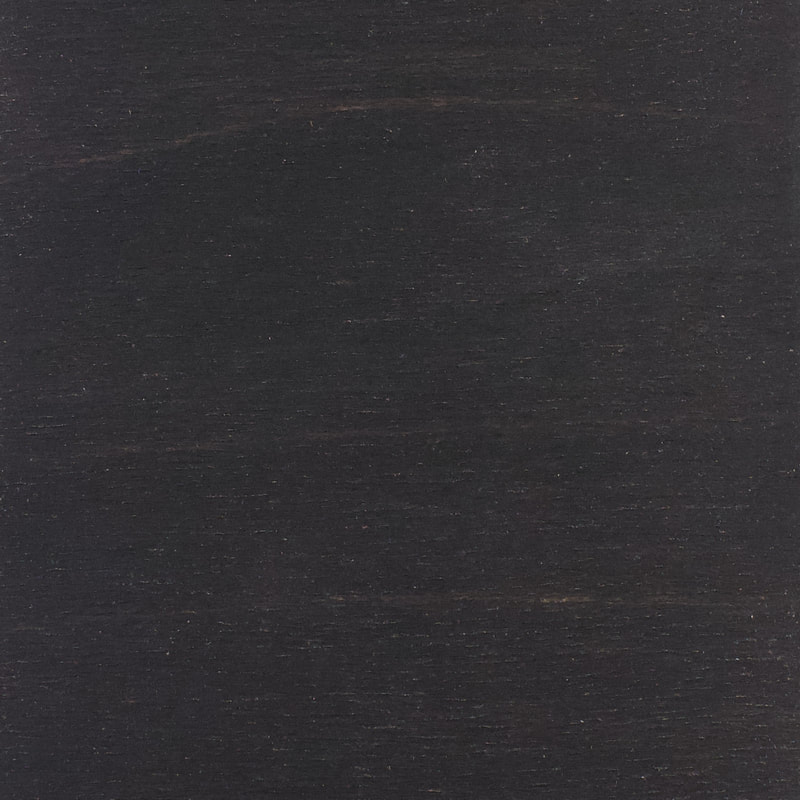

Examples of our most popular colors on Maple.

|

Another something that’s different in the Paint Room from the Paint Store is color matching. TreeHouse doesn’t have one of those take-in-your-carpet-scrap-and-match-its-color machines. Instead, a few color samples are mixed up and applied to scraps of the actual wood used to make your drums. See them as pictures on your computer screen or by holding the scraps in hand. Not quite right? We’ll mix up more and more variants until we get it the way you want. Then we’re left with a recipe that can be repeated — so many cubic centimeters of water with so many drops of this base color plus so many more drops of that base color for YOUR formula — so your drums can be matched years down the road. (Gotta admit, about 3% of the projects over the years can’t be matched—either a recipe wasn’t properly recorded years ago or a prototype finish is applied over some scrap dye lots which can’t be reproduced.)

2. Oil

So what happens once your drums have some color on them? The next step is a hand-rubbed oil that seals everything and adds depth to the wood grain and the colors in wood. Oils used for this purpose are "drying oils" which slowly oxidize in the air and eventually go solid. Because of its relatively quick dry time and excellent results, TreeHouse's go to medium is boiled linseed oil.

3. Wax

After the oil has aired out for a few days, a thin layer of one of four different wax recipes are hand-rubbed on the drums. They’re then burnished. Burnishing is similar to the notion of buffing, but a little more than that. Burnishing wax does three things:

- It grinds the wax into the pores of the wood.

- It removes excess wax so as to leave a uniform layer on the project.

- It heats up the wax causing it to meld to itself—all from the friction of rubbing the wax with a cotton cloth or by engaging a buffing wheel.

TreeHouse uses different kinds of paste wax to produce different finishes.

|

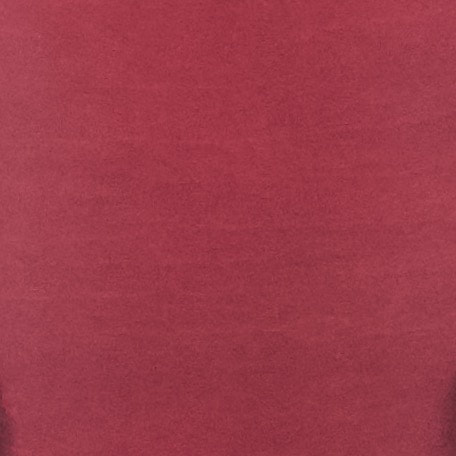

Matte

This finish is for when you want to reduce the amount of reflection to a very small amount. It's really a Matte+ at first, but can settle to a nearly no-reflection appearance after several months. It has been the only Matte we've offered until 2016 when Hardmatte was added; so if you see an older "matte" TreeHouse drum, it's this. |

|

Shiny

This finish is the only one which requires additional fundage. It can actually get too hot when burnishing on a wheel so has to be rubbed by hand and is a mixture of beeswax and carnauba wax with toluene. The toluene keeps it soft and helps deliver the wax into the pores of the wood. The toluene evaporates in a few minutes after application, then the drum smells like honey when we’re a-rubbin’ away. |

As for maintenance of TreeHouse Wax Finishes, it’s really easy! A bit of buffing once a year does wonders. Just rub with the grain using a cotton cloth. If a drum has become dirty and not as lustrous as before, a new layer of wax may needed to be applied which we can do for a small fee. Another thing that’s cool about these wax finishes is that if you really gouge your drum, the finish can be repaired to a like-new appearance (but with the physical scratch or trough you created still present). This can be done quickly, easily, and cheaply since we keep your color recipe on file and can blend new wax over old without any ugly transition zones.

Lastly, all TreeHouse drums’ interiors and bearing edges are hand-rubbed with a material to smooth the surface and seal the wood pores.

Lastly, all TreeHouse drums’ interiors and bearing edges are hand-rubbed with a material to smooth the surface and seal the wood pores.